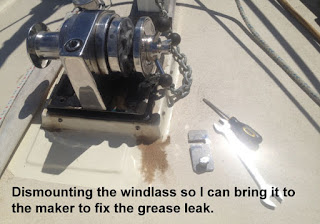

This was the week of the windlass and

the wind. On Friday I drove a couple of hundred miles to bring the

windlass from Ventura to Lighthouse Manufacturing in Riverside, stopping at Minney's Yacht

Surplus on the way back to L.A. The traffic was horrendous most of

the time, but the side trip to Minney's was worth it because I was

able to find a pair of massive chainplates for securing the series

drogue to the stern. And the price was a steal. Monday I reversed

the trip, less the side trip to Orange County. I picked up the

windlass with its new “gate,” new bearings, new seals as well as

new paint and polish. $194. Also met and chatted with the

80-year-old owner of the company. In the process of remounting the

windlass I noticed that the chain stripper had been rubbing against

the gypsy, and it still was. While there was a little play available

to adjust the stipper's position, it wasn't nearly enough. I ended

up having to grind away quite a bit of material on the chainstripper.

Unfortunately, it required a pretty tedious and time-consuming

cycle of grinding and checking to get it right. The end result was

good, though. The modification won't hurt its functionality and it's

still plenty strong enough. It's also pretty much invisible, so it

won't hurt aesthetics either.

On the weather front, (Did I really say

that?!) two full gales hit the area this week. Trees were toppled,

nesting herons killed, and boats and cars coated with sticky brown

grit, inside and out. We even had to dig our canoes out of the sand

and clean the sand out of them out before we could use them tonight.

Yuck!